PAUT of Complex Geometry

Phased Array Ultrasonic Inspection of Complex Geometries:

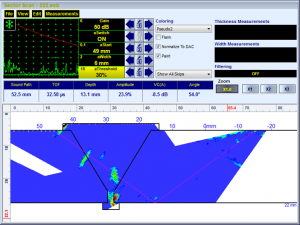

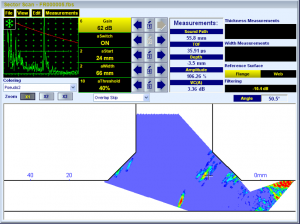

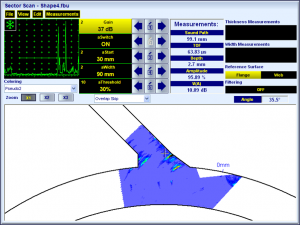

In the past ultrasonic technicians were use to interpreting standard sectorial scans as shown below and using the aid of screen cursors to place defect location, but with the advances in technology developed by Sonotron NDT it is now possible to have a corrected view showing “true geometry correction” of part being inspected.

Developments in Phased Array modeling technology now enables the PA operator a visual real time assessment of complex parts that allow true location of flaws observed.

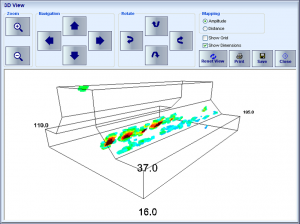

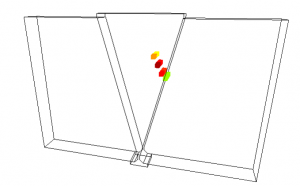

In addition to True Geometry we can also use 3D Modeling software that will give an isometric projection based on the data obtained from ultrasonic inspection. See 3D model below. Any individual slice can also be taken from this view to evaluate further location of flaws and relevant sizes.

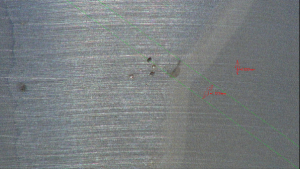

In a recent validation process lack of fusion was being investigated on bevel face when salami slice of section for Macro analysis revealed porosity adjacent to this flaw, further evaluation of 3D Model was able to re-evaluate and locate this porosity and sized at less than 0.5mm diameter. See Images below.

3D Model Slice