Tube Inspection Services

- Tube Inspections Services have been carried out by Advanced NDT Solutions personnel for the Pharmaceutical, Petrochemical and Power Generation for over 15 years. We specialize in Eddy Current and Ultrasonic techniques for both ferrous and non-ferrous tubing. Our line of techniques includes:

- Remote Field Technology (RFT- Ferrous Tubing);

- Near Field Testing (NFT – Fin Fans)

- Eddy Current Testing (ECT- Non-ferrous Tubing);

- Internal Rotary Inspection System (IRIS-Ultrasonic Testing all materials).

Scheduled shutdowns present an opportunity for planned inspection programs which enable continued operation of critical plant equipment by minimizing unexpected failures. Prior to deciding which techniques are most suitable for your needs the following items should be considered: number of tubes to be inspected; cleanliness of tubes and time available for inspection.

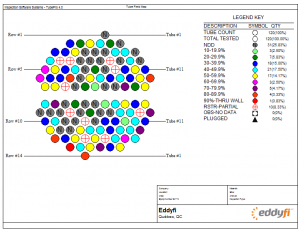

Eddy Current Testing (ECT): This is the most common technique utilized for the inspection of non-ferrous tubing, the technology is very reliable and can determine tube condition in relation to general wall reduction and the presence of local defects such as pitting and cracking with a high probability of detection when using the correct probes. Standard inspection technique for smooth tubing utilizes two separate channels for data acquisition; Absolute (wall reduction) and Differential (local defects). When inspecting finned tubing (chillers) an A/C probe is used to reduce noise associated with fins. Detailed analysis can be performed using software tools which can determine location of defects in relation to ID/OD of tube wall by Phase Analysis from depth curves which are generated from calibration standard. Software tools also allowing for mixing of baffle signature to evaluate flaws hidden behind baffle supports

Remote Field Testing (RFT): This is a fast reliable screening tool for the condition assessment of ferrous tubing (carbon steel, ferritic stainless steel and Duplex). Works typically at very low frequencies (100 Hz to 1 kHz) and very high signal gains (> 80 dB) can inspect up to 12 mm (1/2 in.) of carbon steel pipe. Typically two channels are used for examination, Absolute for wall thinning and Differential for localized defects RFT is very good at wall thinning measurement but less performing to pitting (as compared to ECT). To improve inspection results it is always advised to perform cleaning of the internal bore of tubes with some form of water jet lancing tool.

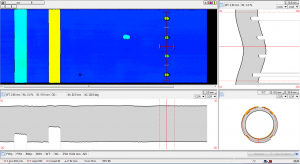

IRIS – Internal Rotary Inspection System: This is an ultrasonic technique for condition assessment of tubing of all materials with a tube wall thickness greater than 1mm. The technology can precisely measure remaining wall thickness from corrosion, erosion, pitting and wear associated with baffle supports. However it requires a very high standard of cleaning and is a much slower technique than the ECT or RFT test methods. It is not possible to detect cracking with IRIS. The system uses a rotating turbine head with a transducer sending a single into tube wall via an angular mirror. The image displayed can be seen as a B-Scan (Cross-sectional view) and also in a C-Scan (Development of Longitudinal axis of tube).

Allow the experts at Advanced NDT Solutions (ANS) develop an inspection solution for your company, we can provide the Answer to obtaining the information you require to continue the safe operation of your plant equipment. Our team has over 15 years experience in delivering advanced ultrasonic technology in the field, prior to their acceptance into construction codes as standard practices. We aim for quality and integrity everyday.